Teknikor will work to tailor an EPM program that meets your facility unique needs

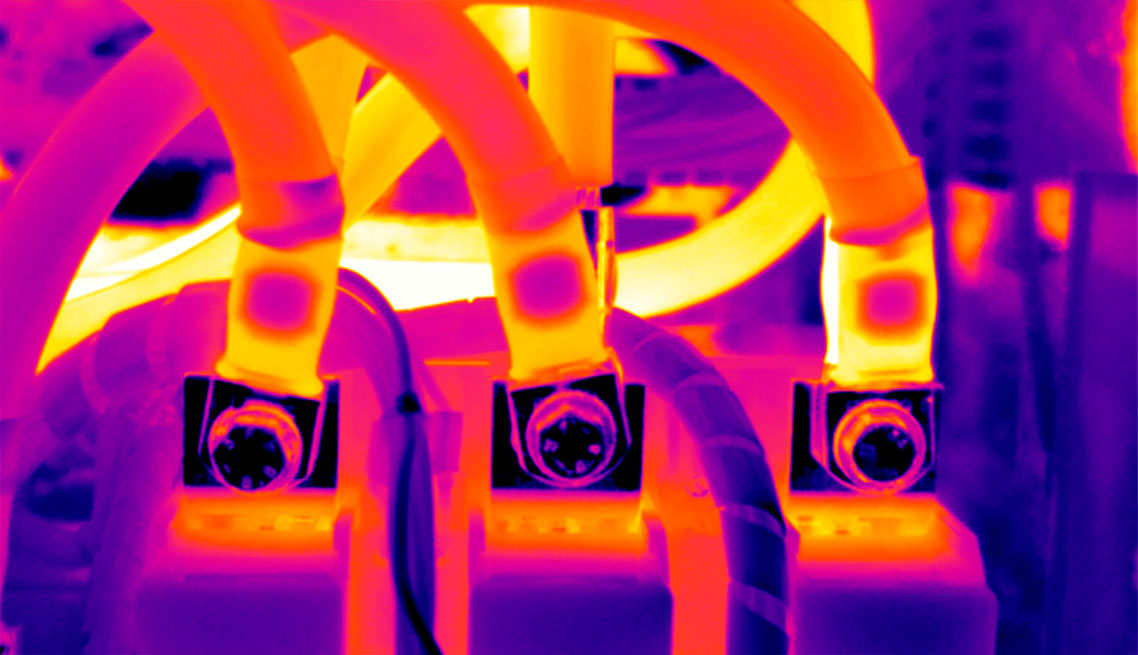

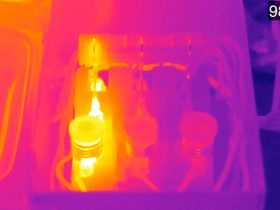

Energized Preventive Maintenance

Diagnostic testing and the most critical preventive maintenance is performed with your system running fully energized under full load. Through infrared, ultrasonic, harmonics, and power factor testing, we can find 99.9% of electrical issues so that catastrophic failures can be avoided. Hazardous conditions can also be detected through visual inspection, and our licensed electricians can keep you up to code.

De-Energized Preventive Maintenance

It is essential to schedule downtime and perform critical maintenance on all electrical equipment. We are a 24/7/365 emergency service business that can fit any schedules to ensure that your equipment is maintained properly and efficiently.

Our maintenance protocols include:

- Inspection and re-torqueing connections to eliminate high resistance connections that waste energy and pose a fire hazard

- Cleaning and vacuuming components to eliminate the risk of electrical explosion or arc flash because dust can be a conductor.

- Resistance testing (megger) bus bars to prevent outages due to faults and poor insulation values

Arc Flash Protection

An Arc Flash Hazard Study, an analysis and assessment of the arc flash and shock hazards at a facility, is to identify the appropriate level of Personal Protective Equipment (PPE) needed for the maintenance personnel at various locations throughout the facility. These locations include switchgear, switchboards, substations, panelboards, motor control centers, and industrial control panels.

The Arc Flash Hazzard Study will determine energy levels and boundary distances, while assisting the owner in complying with the NFPA guidelines enforced by OSHA inspectors.